Melt Shop / Flame and Heat Resistant Fiberglass Covered Hose

Salem-Republic custom manufactures heat and flame resistant hose for the steel and foundry industries. Radiant heat and open flames found in typical melt shop environments are no match for Salem Republic’s reliable fiberglass hose product line.

Heat Resistant Furnace Door Hose – SUPERGLASS II

Supplying cooling water for electric arc furnaces is critical to the manufacture of steel. Extreme radiant heat, open flames, molten slag, and harsh working environments found in melt shops can lead to hose failure. SUPERGLASS II is a heat resistant, flame resistant fiberglass furnace door hose that is ideal for steel mill applications. A 2-ply fiberglass cover resists temperatures up to 1000°F. longer than any single ply fiberglass or Nomex® covered hose. 150 PSI working pressure design allows this furnace door hose to be used in harsher environments due to increased wall thickness and higher working pressure.

| ID | OD | WEIGHT (LBS/FT) | WORKING PRESSURE (PSI) |

|---|---|---|---|

| 0.5" | 0.98" | 0.21 | 150 |

| 0.75" | 1.27" | 0.32 | 150 |

| 1.0" | 1.57" | 0.45 | 150 |

| 1.25" | 1.92" | 0.62 | 150 |

| 1.5" | 2.23" | 0.83 | 150 |

| 2.0" | 2.81" | 1.20 | 150 |

| 2.5" | 3.31" | 1.47 | 150 |

Heat Resistant SUPERGLASS EAF Water Hose

Designed for use in furnace, roof, LMF or Caster mold water supply and return applications, heat / flame resistant SUPERGLASS EAF Water Hose is ideal for systems where torsion movement, vibration, water hammer or heat fatigue lead to unsatisfactory metal hose performance. The elastomeric characteristics absorb and dissipate torsion movement, vibration, and water hammers. The fiberglass cover can be configured to dissipate the maximum amount of heat possible. SUPERGLASS EAF Water Hoses can be furnished with duck and rubber flanges, beaded ends and back up rings or built in nipples with flanges or male pipe threads.

Heat resistant SUPERGLASS Water Hose can be built to resist abrasive wear caused by hose-to hose friction, or resulting from hoses rubbing on furnace infrastructure. Utilizing a vulcanized spiral bumper along specific portions of the hose minimizes damage to fiberglass hose covers.

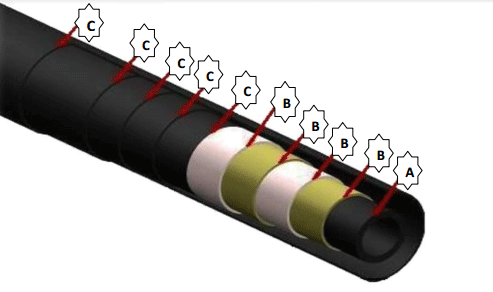

SUPERGLASS Water Hose can be built to accommodate a heat differential along the length of the hose. The basic SUPERGLASS Water Hose relies upon 1 or 2 plies of vulcanized fiberglass over its entire length. In order to address a varying heat profile, up to (4) plies of heat resistant fiberglass can be vulcanized over a specific portion of the hose, at each end of the hose, or over the entire hose length.

Heat Resistant SUPERGLASS Non-Conductive Water Hose

Designed with non-conductive materials, this heat and flame resistant water hose supplies cooling water to mast arm, vault wall, and furnace panel applications.

Typical hose diameters for these applications range from 1″ inside diameter to 5″ inside diameter. A 2-ply fiberglass cover is standard so that the hose can be used in harsh melt shop environments with no additional jacketing. A multiple ply cord or fabric canvass is utilized for discharge applications. A dual plastic helix is utilized in suction and discharge applications proving a user-friendly flexibility never before seen in non-conductive hose assemblies. End configurations include stainless steel swaged on fittings, stainless steel built in nipples, or soft cuffs for on-site distributor coupling attachments.

Extremely harsh steel mill and foundry environments often warrant SUPERGLASS Non-Conductive Water Hoses with unique features including a vulcanized spiral bumper, special couplings, fire sleeves, or a combination of these elements.

SUPERGLASS Oxygen Charging Hose

Designed for melt shop oxygen charging services where typical working pressures require a hose rated for 200PSI, SUPERGLASS Oxygen Charging Hose from Salem-Republic can withstand the harshest steel mill environments. The extruded neoprene tube, dual helix wire reinforcements and fiberglass cover combine to provide the most useful assembly for meltshop oxygen service. The SUPERGLASS Oxygen Charging Hose can withstand pressure hammers, vibration and slag splash due t its rubber/fabric construction and corrugated fiberglass cover. End configurations are generally male pipe thread fittings swaged over soft cuffs.

RHINO SKIN Carbon Powder Injection Hose

Designed for carbon powder injection service, Rhino Skin is built with a static dissipating, 2-part tube, and is more durable and long lasting than sandblast hose. Available in two different versions, Rhino SKIN Carbon Powder Injection hose minimizes downtime in production due to hose changes.

RHINO SKIN

RHINO SKIN is recommended when maximum tube abrasion resistance and cover abrasion resistance is required.

| ID | OD | WEIGHT (LBS/FT) | WORKING PRESSURE (PSI) | LENGTH |

|---|---|---|---|---|

| 1.0" | 1.94" | 1.00 | 150 | 50' |

| 1.25" | 2.20" | 1.16 | 150 | 50' |

| 1.5" | 2.44" | 1.34 | 150 | 50' |

| 2.0" | 2.94" | 1.68 | 150 | 50' |

RHINO SKIN SUPERGLASS

RHINO SKIN SUPERGLASS is recommended when superior tube abrasion resistance is needed in combination with superior heat resistance.

| ID | OD | WEIGHT (LBS/FT) | WORKING PRESSURE (PSI) | LENGTH |

|---|---|---|---|---|

| 1.0" | 1.94" | .90 | 150 | 50' |

| 1.25" | 2.20" | 1.03 | 150 | 50' |

| 1.5" | 2.44" | 1.20 | 150 | 50' |

| 2.0" | 2.94" | 1.50 | 150 | 50' |

Hose Customization Capabilities

Salem-Republic Rubber manufactures Heat Resistant Fiberglass Hose in almost limitless variations based on customer-specific needs.

To learn more about some of the customized hose manufacturing capabilities we offer,

click on a heading below:

Custom Lengths

We can produce heavy-wall hose and high-flexibility tubes up to 50 feet in length, with custom-engineered diameters to match existing process pipe I.D.’s or O.D.’s up to 42 inches.

[/dt_verticaltab_item][dt_verticaltab_item title=”Custom Tube Linings”]

Custom Tube Linings

Based on the types of materials that you will transfer via the hose, Salem-Republic will help you determine the best use of natural and synthetic rubber including quality custom blends.

[/dt_verticaltab_item][dt_verticaltab_item title=”Custom Wall Thickness”]

[/dt_verticaltab_item][dt_verticaltab_item title=”Custom Wall Thickness”]

Custom Wall Thickness

Internal tube and supporting carcass wall thickness is determined based on the nature of specific compounds being handled, total hose diameter, and your service conditions. Salem-Republic’s engineers help make these determinations after getting a description of your hose working environment.[/dt_verticaltab_item][dt_verticaltab_item title=”Reinforcement Options”]

Reinforcement Options

Whether allowing for bends and turns in your process lines, or reinforced to prevent kinking, multi-ply synthetic fabrics and helically wound steel assure maximum tensile strength and ability to withstand movement and vibration in the hose made to your specifications.[/dt_verticaltab_item][dt_verticaltab_item title=”Custom Cover”]

Custom Cover

From wear-resistance to chemical resistance, your hose will be manufactured to meet your specific operating situation based on the nature of specific chemical compounds being handled, and your environment. If required for simple visual identification, hose can be provided with color-coded exterior. Color coding can also include stripes to customize identification tied to your plant safety requirements.

[/dt_verticaltab_item][/dt_verticaltab]

[/dt_verticaltab_item][/dt_verticaltab]

Common Questions About Steel Mill Fiberglass Covered Hose

Q: What are common applications for fiberglass jacketed hose?

A: Furnace door cooling applications, shell cooling applications, roof cooling applications, electrode arm/mast arm cooling, electrode cable cooling applications, oxygen charging, natural gas charging, and carbon powder charging.

Q: What size hoses are manufactured for use in melt shops?

A: Currently the largest is 16″ diameter, but we have the capabilities to produce hose up to 45″ diameter if required.

Q : How many plies of Fiberglass can you vulcanize to the hose?

A: We can apply up to four plies of fiberglass over a specific portion of the hose, at each end of the hose, or over the entire hose length.

Q: Can you make the hoses abrasion resistant as well as heat resistant?

A: A spiral bumper can be vulcanized along specific portions of the hose to minimize the damage to fiberglass hose covers.

Q: How many steel manufacturers are currently using Salem-Republic Rubber fiberglass hoses?

A: Over 20 mills nationally are currently using Salem-Republic Rubber cooling hose and far more are using our manufactured electrode cable cover hoses.