Rubber Linings

Salem-Republic Rubber produces a variety of uncured elastomeric linings. The rubber lining products are all produced at the company’s facility in Sebring, Ohio. Elastomeric linings provide abrasion resistance in material handling and transfer applications as well as corrosion resistance for applications in industries such as water treatment, chemical transfer and storage, and chemical processing equipment. Available in a variety of elastomers, the linings are available in thicknesses from 1/8” – 1/2” and widths from 37” – 65”.

For more information, please view our rubber lining material overview information and specification sheets found below, or contact Salem-Republic for a quotation.

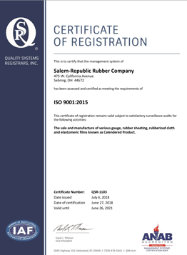

ISO 9001:2015 Certified

Salem-Republic Rubber is ISO 9001:2015 certified for the sale and manufacture of various gauge, rubber sheeting, rubberized cloth and elastomeric films known as Calendered Product.

Quality and manufacturing personnel worked with Quality Systems Registrars, Inc., a leading registration firm, to certify that our quality standard for calendered rubber products is compliant with standards conforming to ISO 9001:2015.

Available Rubber Linings

Natural Rubber

- SR635 – Durometer 35 +/- 5 Shore A – Natural, soft, neutral color, pure gum rubber with no Tie Gum. Use for HCl service. FDA Compliant.

View Lining Specifications >>

- SR640 – Durometer 45 +/- 5 Shore A – Natural, soft, black lining for impact abrasion and Hydrochloric (HCl) Acid resistance.

View Lining Specifications >>

- SR648 – Durometer 40 +/- 5 Shore A – Natural, Tan Gum, with No Tie Gum. Has chemical and abrasion resistance properties. FDA compliant.

View Lining Specifications >>

- SR654 – Durometer 60 +/- 5 Shore A – Natural, soft, black, excellent chemical, tear and abrasion resistance. A highly reinforced compound with Tie gum and antiozonant and antioxidant inhibitors. Good weather resistance.

View Lining Specifications >>

- SR655 – Durometer 60 +/- 5 Shore A – Natural, soft, black, excellent chemical, tear and abrasion resistance. A highly reinforced compound with Tie Gum.

View Lining Specifications >>

- SR656 – Durometer 55 +/- 5 Shore A – Natural, soft, black with Tie Gum and Anitozonants and antioxidants which combine to provide weather protection. Good chemical resistance. Superior machining and grinding qualities without smoky reversion, resulting in a smooth, clean surface.

View Lining Specifications >>

- SR685 – Durometer 90 +/- 5 Shore A – Natural, semi-hard, black. A flexible ebonite lining offering maximum resistance to many chemicals. Without Tie Gum. FDA Compliant.

View Lining Specifications >>

- SR690 – Durometer 90 +/- 5 Shore A – Natural, semi-hard lining for general purpose and water demineralization. FDA Compliant.

View Lining Specifications >>

Neoprene™

- SR960 – Durometer 60 +/- 5 Shore A – 100% Neoprene, soft, black, without Tie gum. Has good abrasion, weathering, corrosion and oil resistance. Self- extinguishing with good machining characteristics.

View Lining Specifications >>

Chlorobutyl

- SR235 – Durometer 65 +/- 5 Shore A – Chlorobutyl, soft, black with Nautral Tie Gum for general purpose chemical resistance with superior abrasion resistance. Not for bleach (NaOCl) service.

View Lining Specifications >>

- SR255 – Durometer 55 +/- 5 Shore A – Chlorobutyl with Natural Tie Gum. Special lining for general purpose chemical service and excellent use with super phosphoric acid service and some oxidizing chemicals. Good heat resistance. Not recommended for Bleach (NaOCl) service.

View Lining Specifications >>

Bromobutyl

- SR215 – Durometer 60 +/- 5 Shore A – Black, Bromobutyl with Tie Gum. Has excellent high temperature resistance, able to handle acid and caustic solutions up to 260°F (127°C). FDA compliant.

View Lining Specifications >>

Rubber Lining Cross Reference Chart

For product specifications, click the red “View Specifications »” link in the row of the product you are interested in.

| Polymer | Durometer | Salem-Republic | Specifications | Blair | Poly-Corp |

|---|---|---|---|---|---|

| Natural | 35 +/- 5 | SR635 | View Specifications » | PG70 | 2000 |

| Natural | 45 +/- 5 | SR640 | View Specifications » | VE412BN / LS553 | 2002 |

| Natural | 40 +/- 5 | SR648 | View Specifications » | VE411TN / LS556 | 1099 |

| Natural | 55 +/- 5 | SR654 | View Specifications » | LS551 | 2033 |

| Natural | 60 +/- 5 | SR655 | View Specifications » | VE611BN | 1060 |

| Natural | 60 +/- 5 | SR656 | View Specifications » | Δ | 1069 |

| Natural | 90 +/- 5 | SR685 | View Specifications » | Δ | Δ |

| Natural | 90 +/- 5 | SR690 | View Specifications » | VE821BNS | 1048 |

| Neoprene | 60+/- 5 | SR960 | View Specifications » | VE610BNE / LS575 | 2010 / 2012 |

| Chlorobutyl | 65 +/- 5 | SR235 | View Specifications » | VE628BC | Δ |

| Chlorobutyl | 55 +/- 5 | SR255 | View Specifications » | VE621BC | 1055 |

| Bromobutyl | 60 +/- 5 | SR215 | View Specifications » | HB50HT | 6512 |

Δ = No equivalent liner available from this manufacturer