SR215 Bromobutyl Rubber Lining

This Bromobutyl rubber lining material provides excellent high temperature resistance, able to handle acid and caustic solutions up to 260°F (127°C). It is also FDA compliant.

Lining Specifications

Lining Code: SR215

Type: Bromobutyl (Black)

Tie Gum: With Tie Gum

Properties: 60 +/- 5 Shore A – Black, Bromobutyl, with Tie Gum, excellent high temperature resistance, able to handle acid and caustic solutions up to 260°F (127°C). FDA compliant.

Primers and Adhesive System:

- One coat Chemlok® 289 on Metal

- One coat Chemlok® 290 on Metal

- One coat Chemlok® 286 on Metal

- One coat Chemlok® 286 on Lining

Follow Lord® adhesive recommended procedures for mixing and set time.

Seams and Cap use SRCE262CIIR Tack Cement

*Sufficient tack time is crucial to obtain maximum bond.

Cure Time and Temperature:

Cure for thickness up to ¼”

| Pressure, Saturated Steam (Autoclave) | 2 hrs. @ (40 psi) 290°F (143°C) |

| Internal Steam Cure | 8 hrs. @ (20 psi) 260°F (126°C) |

| Atmosphere Steam Cure | 48 hrs.@ 200°F (94°C) |

Note: All reference to cure psi represents gauge pressure.

**Cure times may require tunings to compensate for low temperatures, heavy metal thicknesses, and other anomalies. Contact SRR Technical Department for recommendations on lining thicknesses over ¼”.

Storage

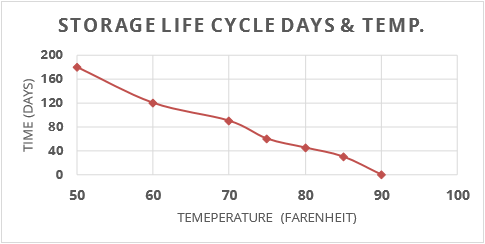

Ideal storage temperature is 50°F not to exceed 85°F and shelf life is 180 to 45 day range respectively.

Ideal storage temperature is 50°F not to exceed 85°F and shelf life is 180 to 45 day range respectively.

Depending on storage conditions it may be possible to use rubber linings beyond shelf life. Please contact Salem-Republic Rubber Company for technical advisement before usage.

Designed Physical Properties

| Tensile Strength PSI | ASTM D412 | 1200 min |

| % Elongation at Break | ASTM D412 | 350 min |

| Durometer | ASTM D2240 | 60 +/- 5 A |

| Specific Gravity | ASTM D297 | 1.36 |

| Adhesion to Metal | ASTM D429 | 30 pli min |

Skive:

- Open (Without Tie Gum)

- Closed (With Tie Gum)

Repair lining: SR215

Application Suggestions

- SR215 lining shows acceptable rubber to metal adhesion with Tie Gum.

- For gauges greater than ¼” plying up to desired thickness is recommended using a 45°/135° butt splice with offset seams on all but the top layer.

- When plying up, the first layer can be installed without or with Tie Gum. The Tie Gum on subsequent layers is not necessary, therefore the top layer may be lapped with an open skive.

- Use a heated table that warms rubber to approximately 120°F(49°C) prior to applying linings and Cap Strips.

- Experienced applicators may have techniques which produce equal or superior results and by no means are Salem-Republic Rubber Company’s application suggestions meant to replace these proven techniques. As long as those procedures fall within industry standard lining application guidelines.

Standard Dimensions

Roll Standard Gauge Tolerance Roll Gauge Standard Roll Maximum

A Roll .120 +/-.05 A Roll 90ft 96

B Roll .180

+/-.010 B Roll 60ft 66

C Roll .240

+.010 or -.020 C Roll 45ft 51

3/8” Roll .360

+/-.015 3/8” Roll 30ft 33

½“ Roll .480

+/-.015 ½“ Roll 23ft 27

*Customer specific gauges and widths, other than standard, are available upon request. Please call Salem-Republic Rubber Company at 1-877-425-5079 with any questions or more information about our Custom Elastomeric Linings.